A complete analysis of the structure and telescopic principle of the truck crane boom

The boom of a truck crane, as its core component, plays a vital role. The crane connects the hoisting wire rope to the heavy object through the pulley block at the top of the boom, thereby achieving the suspension and transportation of the object. The change of the length and inclination of the boom is the key to adjusting the lifting height and working radius. However, different boom structures and technologies will have a significant impact on the overall performance and operating efficiency of the crane.

1. The boom structure of the truck crane

The boom of a truck crane usually consists of two parts: the main boom and the jib. The main boom is the core component of a truck crane, and its structure type is crucial to the performance of the crane. At present, the main boom of mainstream truck cranes adopts a box-type structure, while the truss structure is relatively rare. The jib is an auxiliary component used to lift lighter objects when the main boom is not high enough. It usually has only one section of boom, but there are also folding or telescopic jibs with more than two sections, among which the folding truss structure jib is more common.

2. Telescopic principle of the boom of the truck crane

(I) Types of telescopic mechanisms of truck crane booms

There are many types of telescopic mechanisms of truck crane booms, including sequential telescopic mechanisms, synchronous telescopic mechanisms, independent telescopic mechanisms, and combined telescopic mechanisms. The characteristic of the sequential telescopic mechanism is that each boom section is telescoped one by one in a certain order. The synchronous telescopic mechanism ensures that each boom section of the telescopic boom is telescoped synchronously at the same relative speed. The independent telescopic mechanism allows each boom section to telescope independently, providing great flexibility. When the telescopic boom has more than three sections, the combined telescopic mechanism can use any two of the above telescopic methods to work at the same time.

(II) Technical classification of telescopic mechanism

The telescopic mechanism of automobile cranes can also be classified from a technical perspective, mainly into two categories: pinless full hydraulic telescopic mechanism and automatic pin-type telescopic mechanism.

1. The advantage of the pinless full hydraulic telescopic mechanism is that its arm length is easy to adjust and the working arm length is diverse, which greatly enhances its practicality. However, its own weight is heavy, which has a certain impact on the stability of the whole machine. In addition, this telescopic mechanism can be combined in a variety of ways, such as multiple hydraulic cylinders with a first-stage rope row, or a single hydraulic cylinder or multiple hydraulic cylinders combined with a two-stage rope row. Among them, the combination of multiple hydraulic cylinders plus a first-stage rope row is characterized in that the last telescopic arm is telescoped by a wire rope, while the other telescopic arms are telescoped directly by a multi-stage cylinder or multiple single-stage cylinders, or even a combination of a multi-stage cylinder and a single-stage cylinder. This design results in a significant change in the cross-section of the last telescopic arm, while the cross-section changes of other arm sections are relatively small.

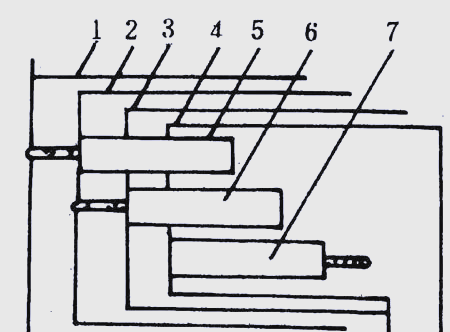

Schematic diagram of the telescopic mechanism of multiple hydraulic cylinders and a first-level rope row

1-basic boom; 2-two-section boom; 3-three-section boom; 4-four-section boom; 5-first-level cylinder; 6-second-level cylinder; 7-third-level cylinder

2. The automatic latch-type telescopic mechanism adopts a single cylinder design, equipped with interlocking cylinder pins and arm pins, and precise length measurement electronic technology. The advantages of this mechanism are light weight, minimal impact on the stability of the whole machine, rapid telescopic speed, uniform change of boom cross section, and excellent lifting stiffness. However, due to its high technical requirements, it also brings higher costs accordingly, and there are relatively few types of arm lengths on the market.

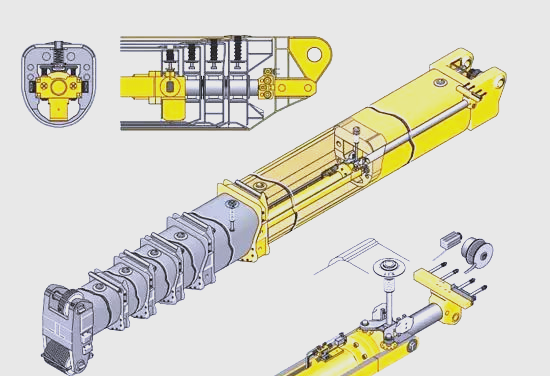

Single cylinder latch crane boom telescopic structure diagram

The automatic latch telescopic mechanism is characterized by its interlocking cylinder pin and arm pin design. The cylinder pins are carefully arranged on both sides of the boom, while the arm pins are designed on the upper plane of the boom. This structure is not only simple and easy to understand, but also has excellent self-locking function. However, it also has certain shortcomings, especially when pulling out the arm pin with large deformation, some difficulties may be encountered, and it takes multiple back and forth telescoping to successfully pull it out.

A deep understanding of the boom structure and telescopic principle of the truck crane is crucial to grasp the key points of the performance of the truck crane. In this way, users can choose the most suitable truck crane product for themselves according to actual work needs when purchasing.